Shandong Xinkaite Bearing Co., Ltd.

Conveyor Idler,Conveyor Idler Roller,Belt Conveyor Idler,Conveyor Carrier Idler

Shandong Xinkaite Bearing Co., Ltd.

Conveyor Idler,Conveyor Idler Roller,Belt Conveyor Idler,Conveyor Carrier Idler

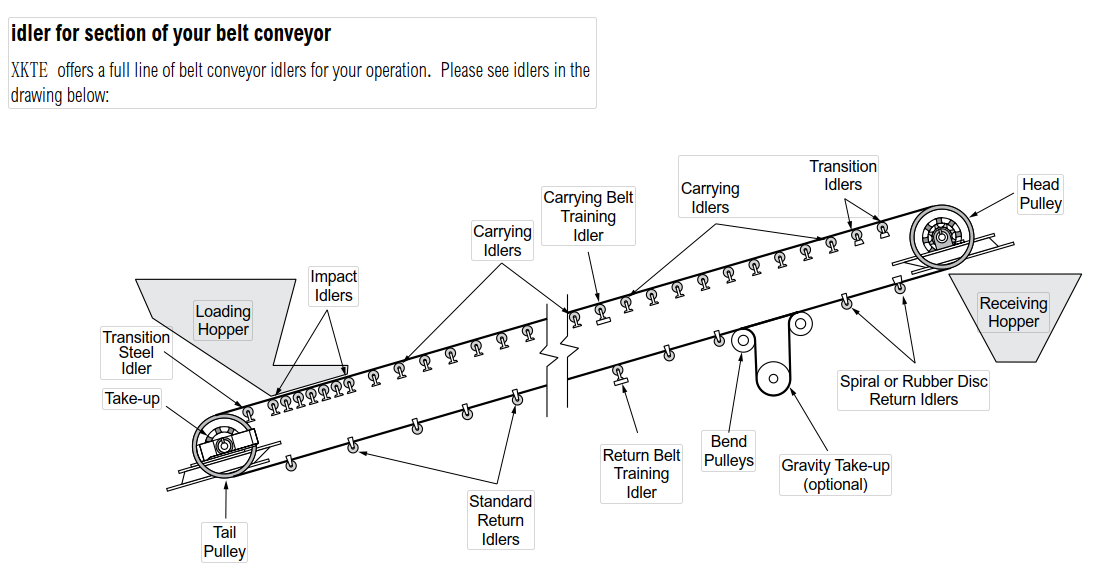

Conveyor idler is the important part of all kinds of belt conveyor, it support the conveyor belt and holds the cargos. Such as Trough Idler, Return Idler, Impact Idler, which meet CEMA, ISO or any other standards. Conveyor idler designs are composed of more than one Roller, where various parts of the idler connect to the conveyor belt at different points to keep the belt properly routed and operating well. These designs can also include metal racks for stability.

As a useful part of many industrial systems, conveyor idlers come in many different forms. Some common ones are inline idlers, inset or offset idlers, and return idlers. Inline, inset, and offset varieties are built in very specific ways to accommodate the belt according to optimal factors. Return idlers often deal with the undercarriage of the belt, which moves in the reverse direction. They can help to control aspects of belt return that contributes to the general function of the conveyor belt, such as the width or tension between the top belt and the return.

Conveyor idlers are used to take up extra belt length and provide adjustment for tensioning belt drives. Idler can be valuable belt drive components. bend Idler can alter belt paths, make the belt clear obstructions, or apply belt pre-tension. Idlers may remain in a fixed location, or may be adjustable to allow belt pre-tensioning and take up. Idlers may be applied to either the inside or backside of belts. Backside idlers are generally flat.

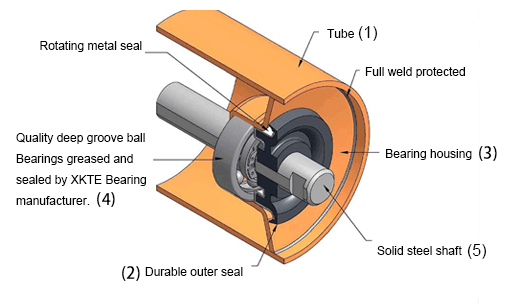

Structure of idler roller:

The internal components of idler rolls are essentially the same

The sealing arrangement protects the bearing from dust and moisture, as well as other environmental contaminants. In addition, the quality of idlers also varies depending on the quality of the individual components and of the manufacturing process. In addition to the idler roll itself, an idler set is supported in position by an idler bracket or base frame. These bases and brackets locate the individual idler rolls relative to each other and provide the necessary 'trough' angle.

1.The outer shells of idler rolls are generally manufactured from 89, 102, 108, 114, 127, 138, 152 and 178 mm tubing.

2.The outer shells are generally closed off with an end cap of varying design.

3. The end caps are normally designed to house the anti-friction bearings (3)

4.and bearing dust seals

5. The anti-friction bearings support the non-rotating idler shaft

The idler shaft has special machined ends to positively location the idler within the base frame support bracket. and every one of our idlers passes through a comprehensive ISO 9001 quality.

Bearing Size

Most manufacturers use 6200 series deep groove ball bearings when constructing B series idlers, and either 6300 series ball bearings or regreasable tapered roller bearings when constructing C series idlers.

Special attention:

For our purposes, most CEMA idler manufacturers publish life expectations for 30,000 hours L10 life at 500 RPM.

| Diameter of roller mm | Length of roller(tube)mm | Bearing |

| 89 | 190.200.230.240.280.305.315.375.380.455.465.600.750.950.1150 | 6204 |

| 108 | 190.200.240.250.305.315.375.380.455.465.525.600.700.750.800.950.1150.1400 | 6205 |

| 133 | 305.350.375.380.455.465.525.530.600.700.790.800.950.1150.1400.1600 | 6305 |

| 159 | 375.380.455.465.525.630.600.640.670.700.750.790.800.900.950.1050.1120.1150.1400.1600 | 6306 6308 |

| 193.7 | 600.640.750.800.900.950.1050.1120 |

|

| 217 | 600.640.1050.1120 |

|